PVC foam board is also known as Chevron board and Andi board. Its chemical composition is polyvinyl chloride, so it is also known as polyvinyl chloride foam board. It is widely used in bus and train car roofs, box cores, interior decorative panels, building exterior panels, interior decorative panels, office, residential and public building partitions, commercial decorative shelves, clean room panels, ceiling panels, stencil printing, computer lettering, advertising signs, display boards, sign panels, album boards, and other industries as well as chemical anti-corrosion projects, thermoformed parts, cold storage panels, special cold preservation projects, environmental protection panels, sports equipment, aquaculture materials, seaside moisture-proof facilities, etc. The board for environmental protection, sports equipment, breeding materials, seaside moisture-proof facilities, water-resistant materials, aesthetic materials and various lightweight partitions instead of glass canopy, etc.

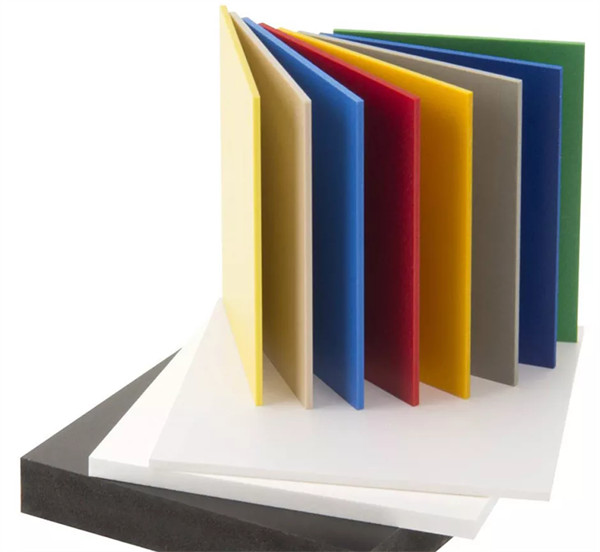

PVC foam board is a better alternative to traditional wood, aluminum, and composite panels. PVC foam board thickness: 1-30mm, density: 1220 * 2440 0.3-0.8 PVC board is divided into soft PVC and hard PVC. Hard PVC board sells more in the market, accounting for up to 2/3 of the market, while soft PVC board accounts for only 1/3.

Hard PVC sheet: reliable product quality, the color is generally gray and white, but according to customer needs to produce PVC color hard board, its bright colors, beautiful and generous, the quality of this product implementation GB/T4454-1996, has good chemical stability, corrosion resistance, hardness, strength, high strength, anti-UV (aging resistance), fire resistance and flame retardant (with self-extinguishing), insulation performance

The product is a superior thermoforming material that can be used to replace some stainless steel and other corrosion-resistant synthetic materials. It is widely used in the chemical, petroleum, electroplating, water purification and treatment equipment, environmental protection equipment, mining, medicine, electronics, communication, and decoration industries.

According to the production process, PVC foam board can also be divided into crust foam board and free foam board; the different hardness of the two lead to very different application fields; crust foam board surface hardness is relatively high, generally speaking is very difficult to produce scratches, commonly used in construction or cabinets, whereas free foam board can only be used in advertising display boards due to its lower hardness.

Post time: Jan-11-2023